Cement City

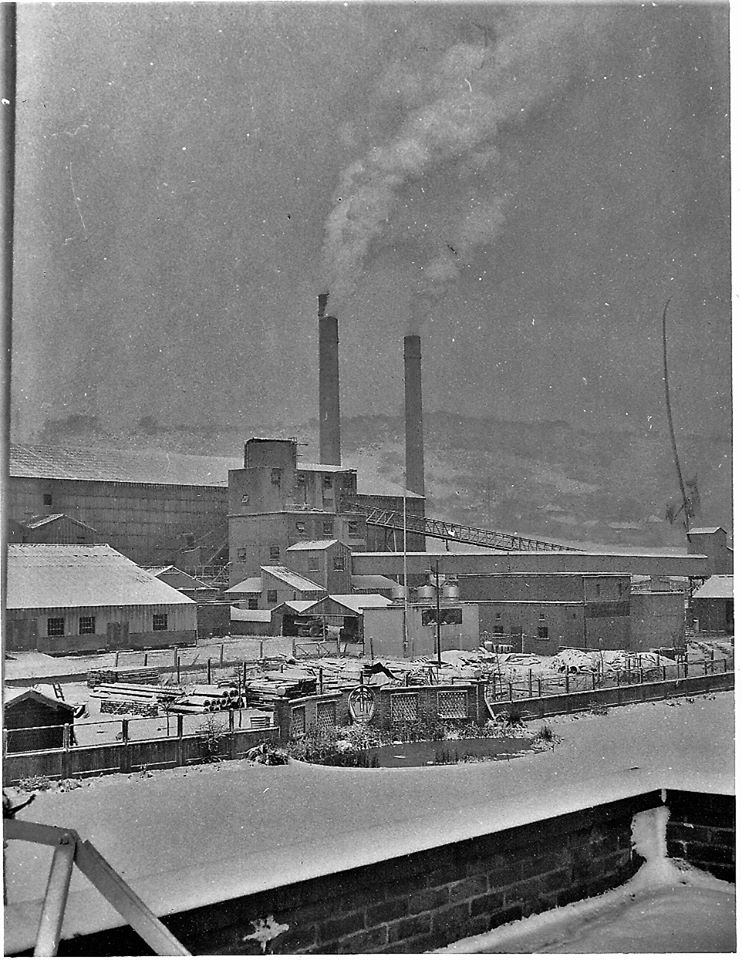

There are still many folk in Halling who will tell you of the days when the village was a centre of the lime and cement industry, and was 'fondly' known as Cement City. Consequently the village was usually covered in a fine white blanket of chalk and cement dust which was on everything from the tops of cars to the roofs of houses. Window cleaners must have been in steady demand. The upside was that the chalk, lime and cement industries gave steady work to hundreds of local men and boys and led to much of the housing along Essex and Kent Roads and the High Street.

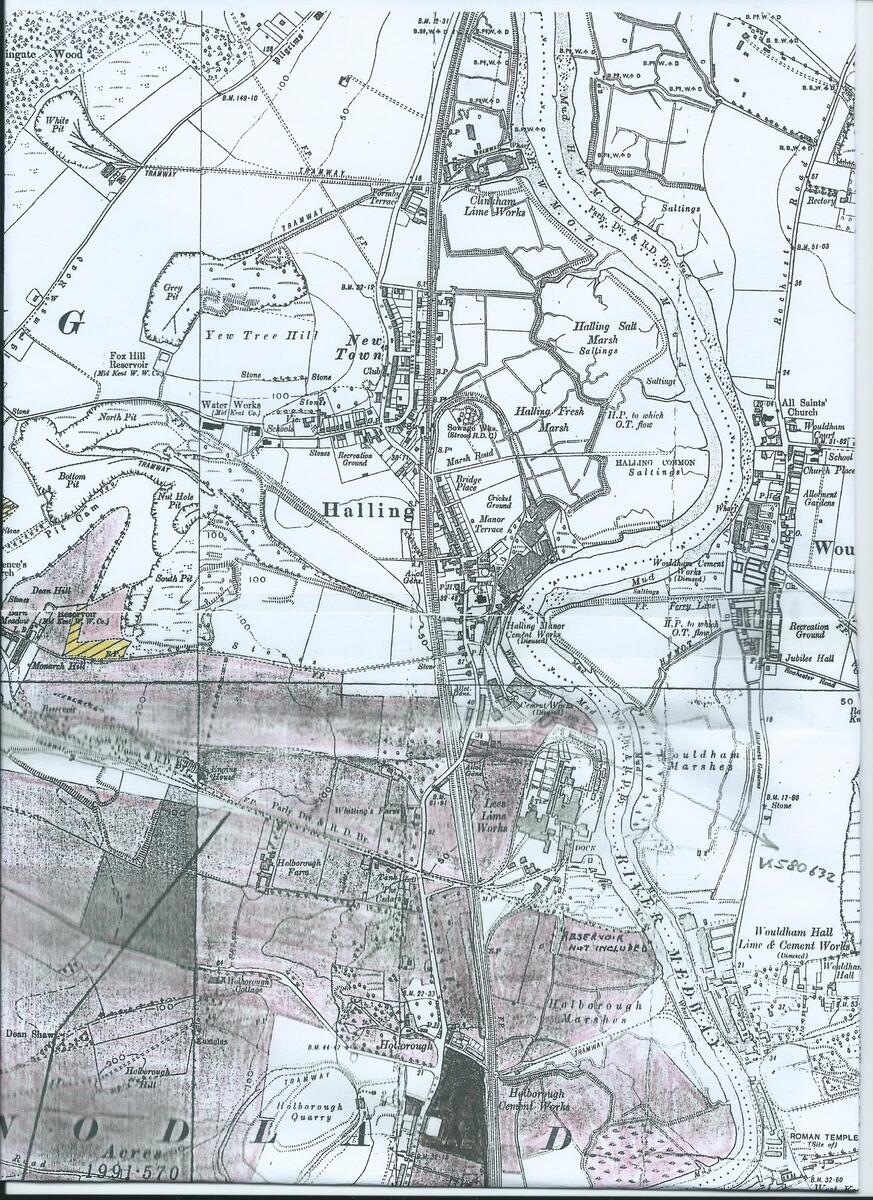

From the 1750s onwards the landscape of the the Medway Gap between Rochester and Aylesford had changed substantially from an overwhelmingly agricultural area to one of many chimneys and industrial works. In the early days a single kiln for lime burning was often associated with one chalkpit but businesses became steadily larger so by the 1820s Messrs Poynder and Hobson were said to be burning a very great quantity of lime at a site on the border of Snodland and Halling. Further to the north of Halling Joliffe and Banks had a substantial works close to the village. Cutbush, Cutbush and Jarvis operated a two acre site at Whornes Place on the border between Cuxton and Halling from 1799.

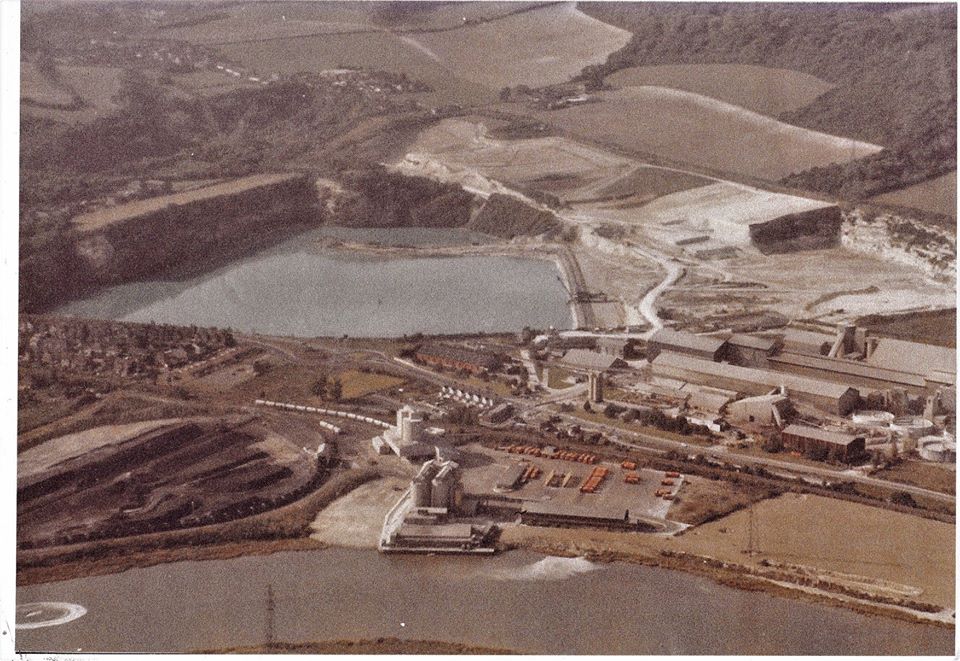

Most quarrying in the area was for chalk. The lower Medway Valley had particular advantages which encouraged the development of the industry with easily accessible chalk on the valley sides and cheap bulk transport by barge along the River Medway. Quarrying really took off with the emergence of brick and cement industries in the valley. All the materials needed for the manufacture of bricks and cement - chalk, sand, gravel. brick earth, clay, and mud were found locally in deposits that could be exploited relatively easily. All these minerals were found close together which minimised transport costs. Around 1831 chalk pits alone employed more than forty men in Halling.

During the 1850s Charles Formby son of the vicar of Frindsbury started a lime works at Halling using a pit just to the west of the Pilgrims Road but the company was liquidated in 1909 largely as a result of the uneconomic cost of shipping the chalk. From around 1850 the invention of Portland cement was a big advance and until the 1870s the Thames and Medway had a virtual monopoly of Portland cement manufacture. Even in 1900 some 80% of cement used in Britain was produced in the Medway Valley and a significant proportion of the national output of bricks came from North Kent. The fortunes of the Medway Valley brick and cement industries fluctuated in sequence with the London housebuilding cycle so a building boom during the 1870s coincided with new works established by Messrs Hilton Anderson and Co at Halling Manor in 1878. William Lee opened a lime works in Halling, which also built barges as they were the main transport means for moving the cement down the river.

All this industry led to substantial growth in the population of Halling, rising from around 550 in 1851, to 760 in 1861, 836 in 1871, 1306 in 1881, 2095 in 1891 and a peak at around 2500 in 1901. Many houses were erected mainly by the cement firms themselves, simple at first like Poynder Terrace but towards the end of this era such houses as Manor Terrace were generous in accommodation and well constructed. Others like those houses at Monarch Hill in Upper Halling were constructed of chalk blocks rendered with cement externally. Mr Anderson took a great deal of interest in the local community and the Halling Institute (now the Community Centre) benefited from his largesse. Hiltons gave the lower Recreation Ground to the parish in exchange for land elsewhere.

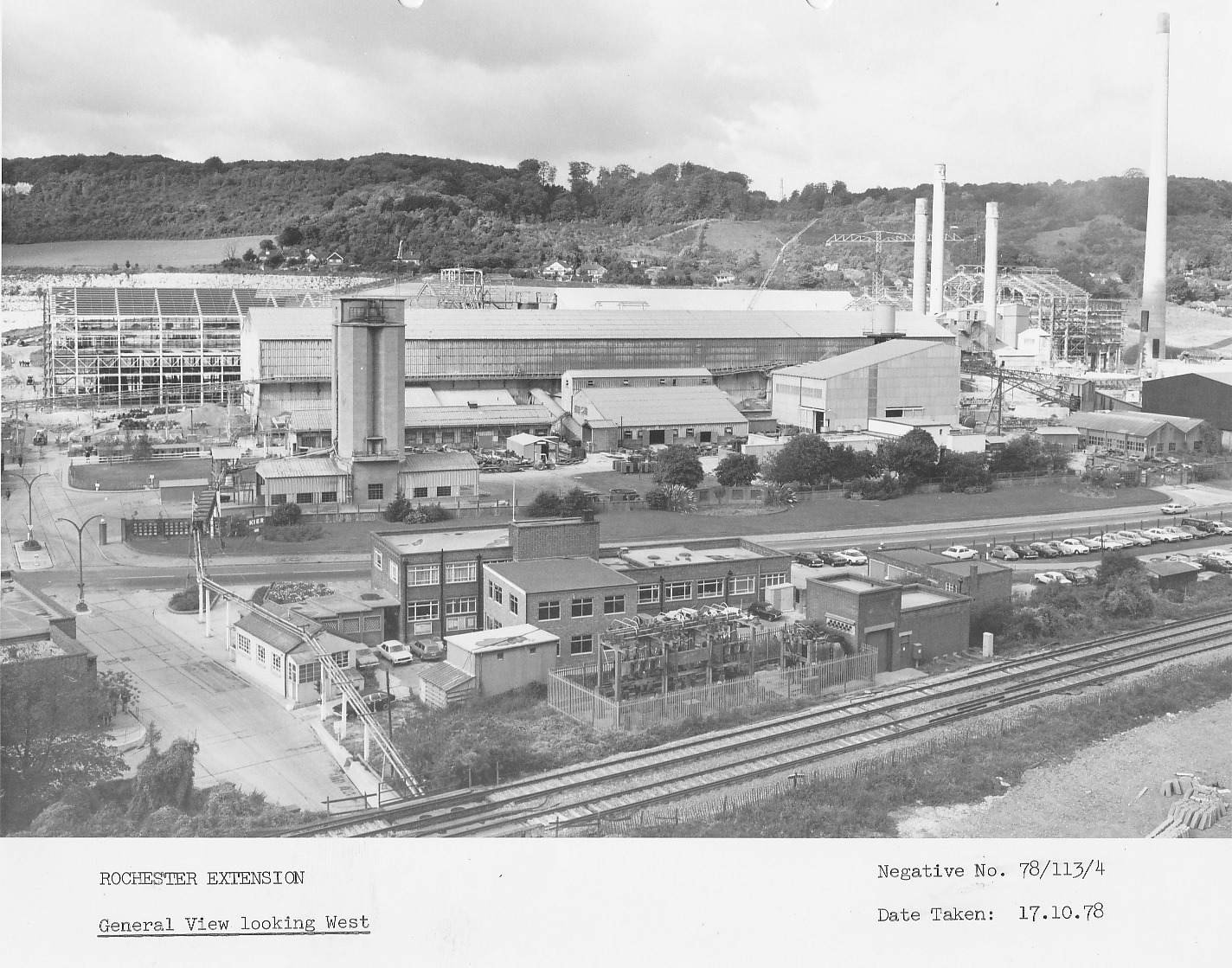

New kiln designs in the 1890s meant technology changed the face of of the local Industries. One of the first to use the latest design of kiln was Martin Earle and Co of Halling. Having been formed in 1878, the Halling Manor lime and cement works operated by Hilton Anderson and Company changed its name in 1893 to Hilton Anderson Brooks and Company Limited following an amalgamation when they became the second largest cement firm in Britain. Severe competitive pressures combined with the new technologies led to consolidation in the cement industry and the two small Halling firms joined together with twenty-five other companies to form the Associated Portland Cement Manufacturers (APCM) in 1900. By 1918 ninety per cent of cement production in the Thames and Medway region was in the hands of APCM. Still, wages were good in the cement industry and far better than in agriculture and many workers in and around Halling prospered.

Manor Works closed in about 1925 followed by Lees in 1930. There remains just one works associated with the cement industry, the Cemex works north of Formby Terrace, opposite St Andrews Park,

Much of the land around Halling and up on the North Downs is still in ownership by a cement company, and has changed hands many times over the years . . . .Blue Circle . . . .Rugby Cement . . .Cemex . . . .Lafarge . . . .Tarmac. If you wander up on the ridge above Halling you can still find signs on fences for nearly all those companies . . . . . .their legacy for years of involvement in Halling as Cement City.

The last cement works chimney in Halling was only demolished in September 2010. Now the St Andrews Park housing development stands on that site. See the videos below, and at bottom of page, of the spectacular blowing up of that chimney.

https://www.youtube.com/watch?v=LhdF-FpJIIk

https://www.youtube.com/watch?v=sTljJpY-JNg

Information from:

'The Medway Valley - a Kent landscape transformed', by Andrew Hann, 2009, Phillimore & Co Ltd.

'Across the Low Meadow - A history of Halling in Kent', by Edward Gowers and Derek Church, 1979, Christine Swift Bookshop.